Shell Pernis

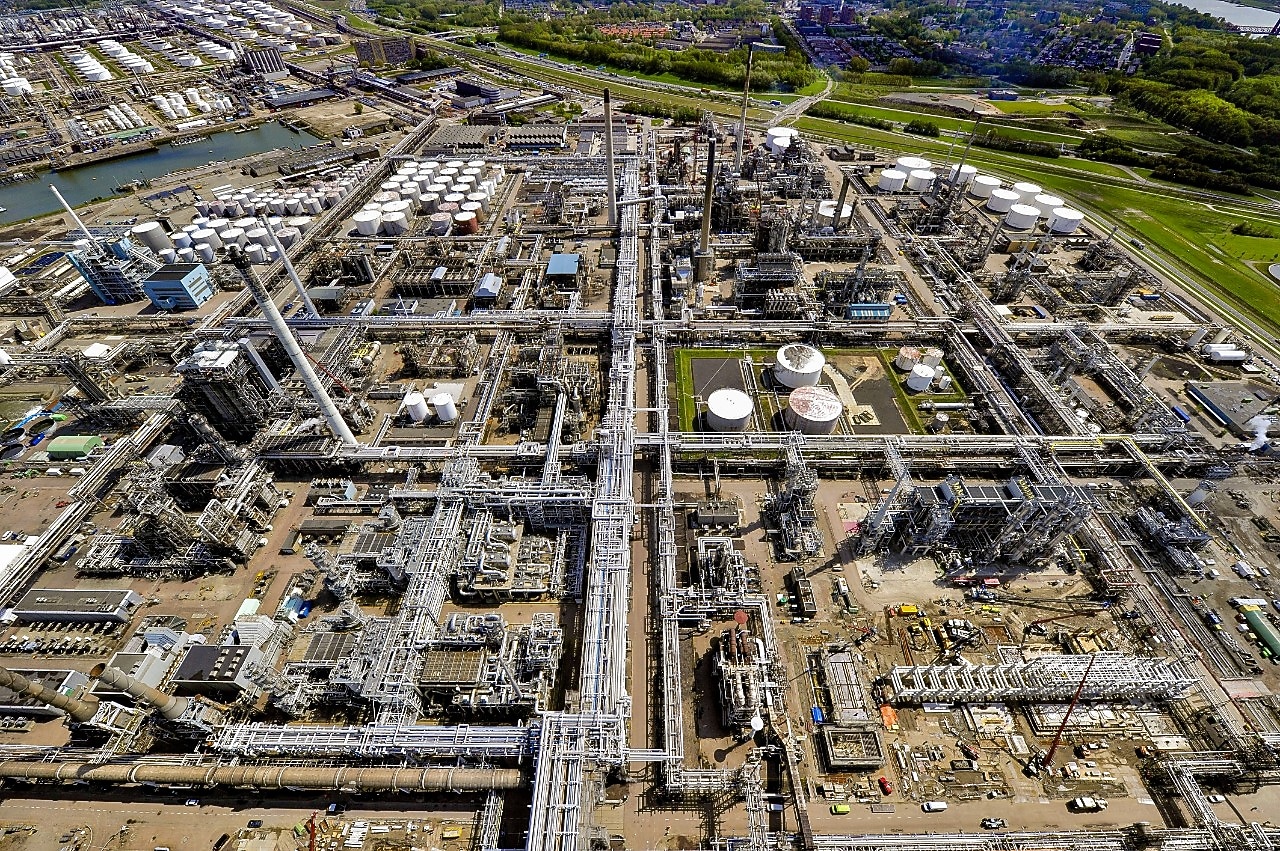

Welkom op de webpagina's van Shell Pernis, de grootste raffinaderij van Europa. Op het bedrijfsterrein nabij Rotterdam staan zo'n 60 verschillende fabrieken.

Grootste van Europa

Met meer dan 60 fabrieken is Shell Pernis de grootste raffinaderij van Europa. Hier wordt ruwe olie omgezet in tal van producten, voor de energie van vandaag en voor jou. Gelijktijdig werkt Shell in Pernis aan het verminderen van haar uitstoot en zet zich in voor de energie van morgen.

Laatste nieuws

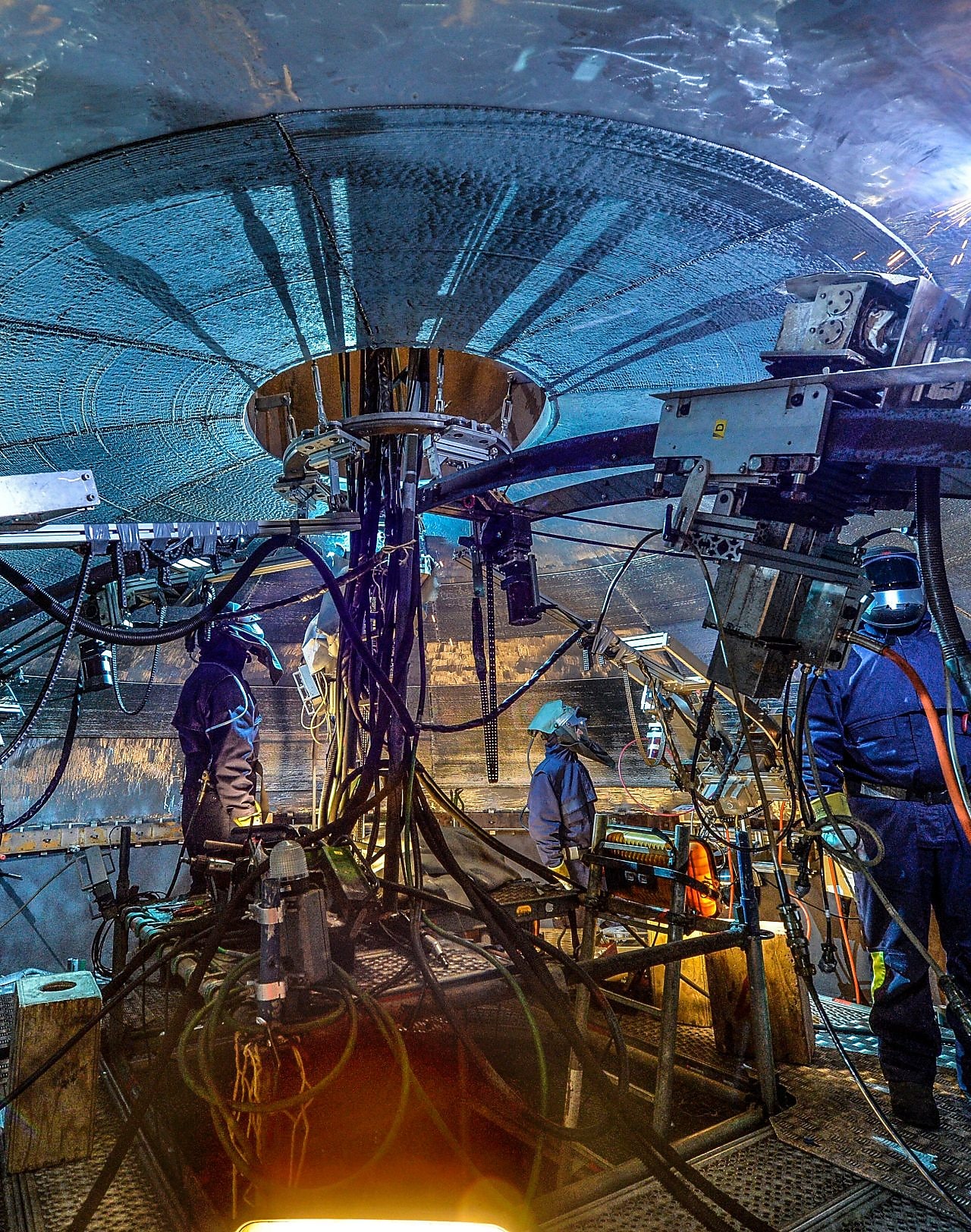

Technologische tegenhanger openhartoperatie Pernis succesvol

Het is de technologische tegenhanger van een openhartoperatie: een onmisbaar onderdeel vervangen terwijl de installatie gewoon blijft doordraaien. Dat is nooit zonder risico, maar medewerkers van de Shell-raffinaderij in Pernis deden het. Zij vervingen vorige week het ‘hart’ van de cat cracker, terwijl de fabriek tijdens de werkzaamheden veilig in bedrijf bleef.

Shell Pernis en Linde gaan stroom delen in een e-hub

Shell Pernis en Linde gaan met een energiehub (e-hub) stroom delen op hun terrein in de Rotterdamse haven. Deze stroom gebruikt Linde om de afgevangen CO₂ van de raffinaderij onder druk te brengen, zodat het naar CO₂-transport- en opslagproject Porthos kan. Netbeheerder Stedin heeft geholpen om de e-hub tot stand te brengen. Deze samenwerking is een concreet voorbeeld van hoe industriële partijen elkaar kunnen versterken in de energietransitie: er zijn mogelijkheden, ondanks de file op het stroomnet.

Carrière in Shell: wat als je doof bent?

Stefan de Visser is doof. En toch werkt hij bij Shell Pernis in de Centrale Werkplaats, met draaiende machines en bewegende delen. Als opgeleid onderhoudswerktuigbouwkundige reviseert hij pompen en compressors. Terwijl veel bedrijven huiverig zijn voor alleen al het bieden van een stageplaats aan een dove bankwerker, kreeg Stefan bij Shell Pernis wel een kans.

Nieuw pleidooi voor behoud Nederlandse basisindustrie

Samen tegen de deïndustrialisatie van Nederland en met de overheid werken aan concurrerend duurzaam worden. Om zo te bouwen aan een toekomstbestendige economie die werkt voor mens, milieu en Europa. Dat is in het kort de inhoud van het op 1 december verschenen pleidooi “Een basisindustrie om op te bouwen: nu & in de toekomst” van de Industriecoalitie. Shell onderschrijft de conclusies van dit bidbook, gemaakt door het platform van bedrijven en belangenverenigingen uit de Nederlandse basisindustrie.

Shell Buurtfonds: eerste uitreikingen gedaan

12 november 2025 | Met het Shell Buurtfonds stelt Shell geld beschikbaar voor lokale initiatieven in de regio’s rondom Shell Pernis en Shell Chemicals Park Moerdijk. Inmiddels zijn de eerste uitreikingen gedaan. Meer weten? Bekijk de video of ga naar shell.nl/buurtfonds.

Shells activiteiten in Pernis

Olie en gas

Shell heeft tot doel om tegen 2050 een bedrijf te zijn met netto nul uitstoot en tegen 2030 haar eigen uitstoot terug te brengen tot de helft. Om zeker te zijn van energie zullen de economie en de maatschappij, dus iedereen, nog een poos afhankelijk zijn van olie en gas.

Transcript

Transcript

Shell Energy and Chemicals Park Rotterdam maakt producten voor vandaag en voor morgen.

Je staat er waarschijnlijk nooit bij stil, maar de producten die worden gemaakt door Shell in Pernis zie je overal om je heen.

In de gel voor je haar…

In deze nagellak…

En de zolen van je sneakers

Shell bouwt een landelijk netwerk van snelladers, bij bouwmarkten en op de Shell-stations

Maar voor diegene die nog geen elektrische auto heeft, maakt Shell in Pernis benzine en diesel.

Je denkt misschien dat deze band van rubber is, uit de rubberboom… Maar autobanden zijn gemaakt van synthetisch rubber. Moet jij raden waar dát van gemaakt is…

En wat denk je van dit asfalt? Daar heb je bitumen voor nodig, hetzelfde spul waar veel platte daken van gemaakt worden.

Dit dashboard is van kunststof. Dat wordt gemaakt uit olie.

En dat geldt eigenlijk voor het hele interieur.

Het stuur… het scherm… de knopjes… die stoel die zo lekker zit.

Weet je hoe dat komt? Omdat ‘ie gevuld is met schuim. Ook weer gemaakt uit olie.

De basis voor al die producten wordt hier gemaakt. Het Shell Energy and Chemicals Park Rotterdam. In Pernis.

Niet dat je hier je nieuwe banden kunt bestellen of een potje nagellak… Maar wel de materialen waarmee andere fabrikanten die kunnen maken. En natuurlijk maken ze er ook brandstoffen voor auto’s, vrachtwagens en vliegtuigen. Benzine, diesel en kerosine, daar is Shell tenslotte het meest bekend om.

Nog niet voor alles bestaat een duurzamer alternatief, maar we werken er hard aan.

Met biobrandstoffen en CO2 veilig opslaan onder de Noordzee via het Porthos-project. En op de Maasvlakte wordt een waterstoffabriek gebouwd die groene waterstof gaat produceren uit windmolen op zee. Deze groene waterstof gaat als energie dienen voor onze fabrieken.

Zichtbaar en onzichtbaar zetten we stappen naar schonere energie.

Meer over Shell Pernis

Ongeveer zestig verschillende fabrieken

Op het bedrijfsterrein van het Shell Pernis staan olieverwerkende- en chemische fabrieken. Hoewel de bouwwerkzaamheden tijdelijk onderbroken zijn, zal hier duurzame vliegtuigbrandstof en hernieuwbare diesel geproduceerd worden uit afval. Denk daarbij aan frituurvet en plantenresten.

In ongeveer zestig verschillende fabrieken worden olieproducten en basischemicaliën gemaakt op basis van aardolie. We gaan CO2 onder de grond op te slaan. En zijn we bezig met de bouw van een duurzame waterstoffabriek op de Maasvlakte. Vanwege het klimaat is het voor ons essentieel om onze CO2-uitstoot voortdurend te beperken.

We leveren ruim 400.000 kilo CO2 aan tuinders die hun planten daarvan sneller kunnen laten groeien. En met het Porthos-project willen we samen met partners grote hoeveelheden CO2 veilig onder de grond opslaan. Ook leveren restwarmte, die niet nodig is onze fabrieken, aan gezinnen in Rotterdam die hiermee hun huizen zonder extra uitstoot kunnen verwarmen.

De terminal in Europoort is ook nog onderdeel van Shell Pernis. Deze locatie zorgt voor de ontvangst, de opslag en het verpompen van ruwe olie en nafta. Vanaf dit punt kunnen ook producten naar overzeese markten worden verscheept. Het totale oppervlak van Shell Pernis is 550 hectare. Dit is net zo groot als 1.000 voetbalvelden. Kortom: een groot en belangrijk complex binnen het gebied van de Rotterdamse Wereldhaven.

Wat doen wij?

Er worden per dag 404.000 vaten ruwe olie verwerkt. Dit is 20 miljoen ton per jaar. Als de fabrieken voluit draaien, wordt er 750 liter ruwe olie per seconde verwerkt in de Crude Distillers. De belangrijkste producten die door de raffinaderij worden gemaakt zijn gasolie/diesel, benzine, kerosine, basisoliën (smeermiddelen), LPG en stookolie. De producten die door de chemische fabrieken worden gemaakt zijn polyolen en oplosmiddelen (bijvoorbeeld aceton, alcoholen en glycolethers). De producten worden door pijpleidingen vervoerd. In totaal zijn deze leidingen 160.000 kilometer lang. Dat is ongeveer vier keer de aarde rond. Zo loopt er een directe leiding naar Schiphol om vliegtuigen te voorzien van brandstof.

Veiligheid

We hebben zorg voor onze omgeving en onze medewerkers. Zeker omdat we met vluchtige en brandbare stoffen werken is veiligheid onze kernwaarde. En we spannen ons maximaal in om onze milieuprestaties te verbeteren: we willen voorkomen dat buren ons zien, horen of ruiken.

Fakkelen

Een fakkel is de vlam op een hoge fakkelinstallatie. Shell krijgt vaak de vraag: waarom is fakkelen nodig en hoe past dat in jullie veiligheidsbeleid? Want een fakkel kan dreigend overkomen en het lijkt onnodige verspilling van energie.

Het antwoord is dat fakkelen een belangrijk veiligheidsinstrument is. Door bijzondere omstandigheden kunnen gasvormige producten soms tijdelijk niet verder verwerkt of opgeslagen worden. Fakkelen, beheerst en veilig verbranden, is dan de veiligste oplossing.

Natuurlijk doen we er alles aan om fakkelen te voorkomen. Het is immers jammer om product te verbranden, daar heeft niemand wat aan. We hebben daarom fors geïnvesteerd in fakkelgas-terug-win-systemen. We kunnen dan minder fakkelen en het overtollige gas gebruiken we om de fornuizen van onze fabrieken te stoken. Als er dan toch gefakkeld moet worden, voegen we extra stoom toe. Dit verbetert de verbranding en voorkomt roet. Soms is er echter te veel aanvoer van stoffen die verbrand moeten worden en/of te weinig stoom. Dan is roetend fakkelen onvermijdelijk. Er is dan sprake van een goed zichtbare vlam en zwarte rook. Ook is stank- of geluidsoverlast mogelijk.

Contact

Wij waarderen je feedback

Shell Pernis staat altijd open voor je vragen. Je feedback is zeer waardevol en je persoonlijke gegevens worden met respect behandeld. Ook anoniem kun je je mening delen.

Je kunt altijd contact met ons opnemen via de volgende kanalen:

- Gratis 24/7 Burenlijn: 0800-0238044

- E-mail: CommunicatiePernisMoerdijk@shell.com

- Volg ons via X: @Shell_Pernis

We zullen binnen 2 werkdagen contact met je opnemen om je feedback te bevestigen en eventuele verdere afspraken te maken.

Je kunt ook je opmerkingen en vragen stellen bij je eigen gemeente en bij DCMR voor eventuele milieuoverlast.

Adressen

Bezoekadres

Vondelingenweg 601

3196 KK Hoogvliet

Download hier de routebeschrijving

Postadres

Postbus 3000

3190 GA Hoogvliet

Donatieverzoeken

Shell Pernis

T.a.v. afdeling Communicatie

Postbus 3000

3190 GA Hoogvliet Rotterdam